Machine We Use

-

TRUMPF – 2 Laser Trumatic L-2530 & L-2510, Trubend press brakes 7036 (2), 5130, and 5085

-

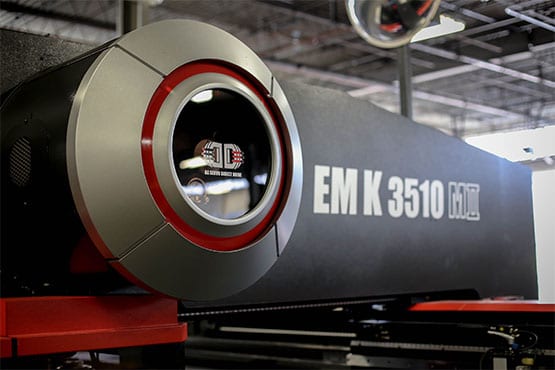

AMADA – 4 punch presses including EMK 3510 M2, Astro-100, RG-125, RG-100, RG-50, FAB-125 press brakes

Blanking- Lasers, Turrets

Precision cutting depends on the situation, and Newburgh Metals has the versatility that sets us apart. Our laser cutters offer the highest precision and cleanest cut for materials up to 1/2″ thick. Our TrumpfTrumatic L-2510 is fully automated and is capable of selecting and loading materials from any of its four trays, running multiple parts in a production plant, and unloading a finished sheet, while the L-2530 offers the fastest turnaround time because this machine has no tooling and utilizes quick and intuitive programming.

In addition to our 3 Amada Turret Punch Presses, our newly acquired Amada EMK 3510 M2 Servo-driven Turret Punch Press combines the simplicity of the original clutch and brake technology with the high speeds of the fastest hydraulic ram driven systems. The result is unmatched performance, superior reliability, and lower operating costs.

Forming

Our 14 press brakes include the latest from Trumpf, and they are capable of bending parts with multiple bends with just one setup. These brakes are CNC driven and allow us to bend large quantities of parts in a small amount of time - saving you both time and money.

Hardware Insertion

Newburgh Metals has a variety of fastener installation machines like the Pemserter automatic installation press system that has established itself as the leader in the world of fastener installation. We can install your fasteners, increase durability, and speed that cannot be met by others.